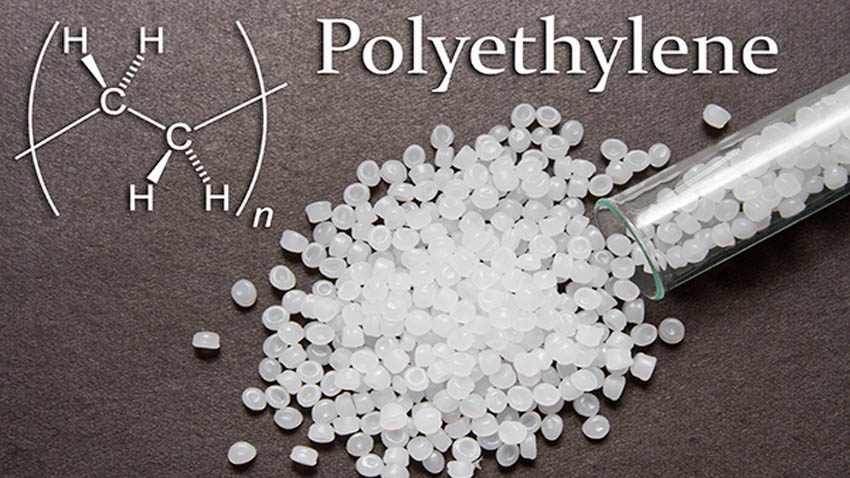

Polyethylene (PE), a member of the important family of polyolefin resin, is the most widely used plastic in the world. They are prepared by the catalytic polymerization of ethylene. It is a thermoplastic polymer consisting of long chains, produced by combination of the monomer molecules, i.e., ethylene. Depending on the mode of polymerization, three basic types of PE are frequently used: linear HDPE, branched LDPE, and LLDPE . PEs are crystalline thermoplastics that possess toughness, excellent chemical resistance and excellent electrical insulating properties, near-zero moisture absorption, low coefficient of friction and ease of processing. Their heat deflection temperatures are reasonable but not high.

HDPE possesses greater stiffness, rigidity, improved heat resistance, and increased resistance to permeability than LDPE and LLDPE. HDPE has a low degree of branching and thus greater intermolecular forces and tensile strength. It can be produced by chromium/silica catalysts, Ziegler-Natta catalysts or metallocene catalysts . HDPE is produced in molecular weights (MWs), ranging from 10,000 to several million. It has a linear polymeric chain, combined with a high density and melting point [14]. HDPE is used in the production of milk jugs, detergent bottles, margarine tubs, garbage containers, toys, and water pipes and in packaging.